Manufacturing & Production

Our team specializes in high-quality manufacturing and production services, offering a wide range of products including chemicals, chemical fibers, plastics, rubber, and industrial fertilizers. Our state-of-the-art facilities and experienced team ensure precision and consistency in every product we produce.

Whether you're in need of nitrogen compounds, pesticides, or agrochemical products, we provide reliable, efficient production solutions tailored to meet the unique demands of your industry. With a focus on quality and sustainability, we are committed to delivering products that help your business thrive.

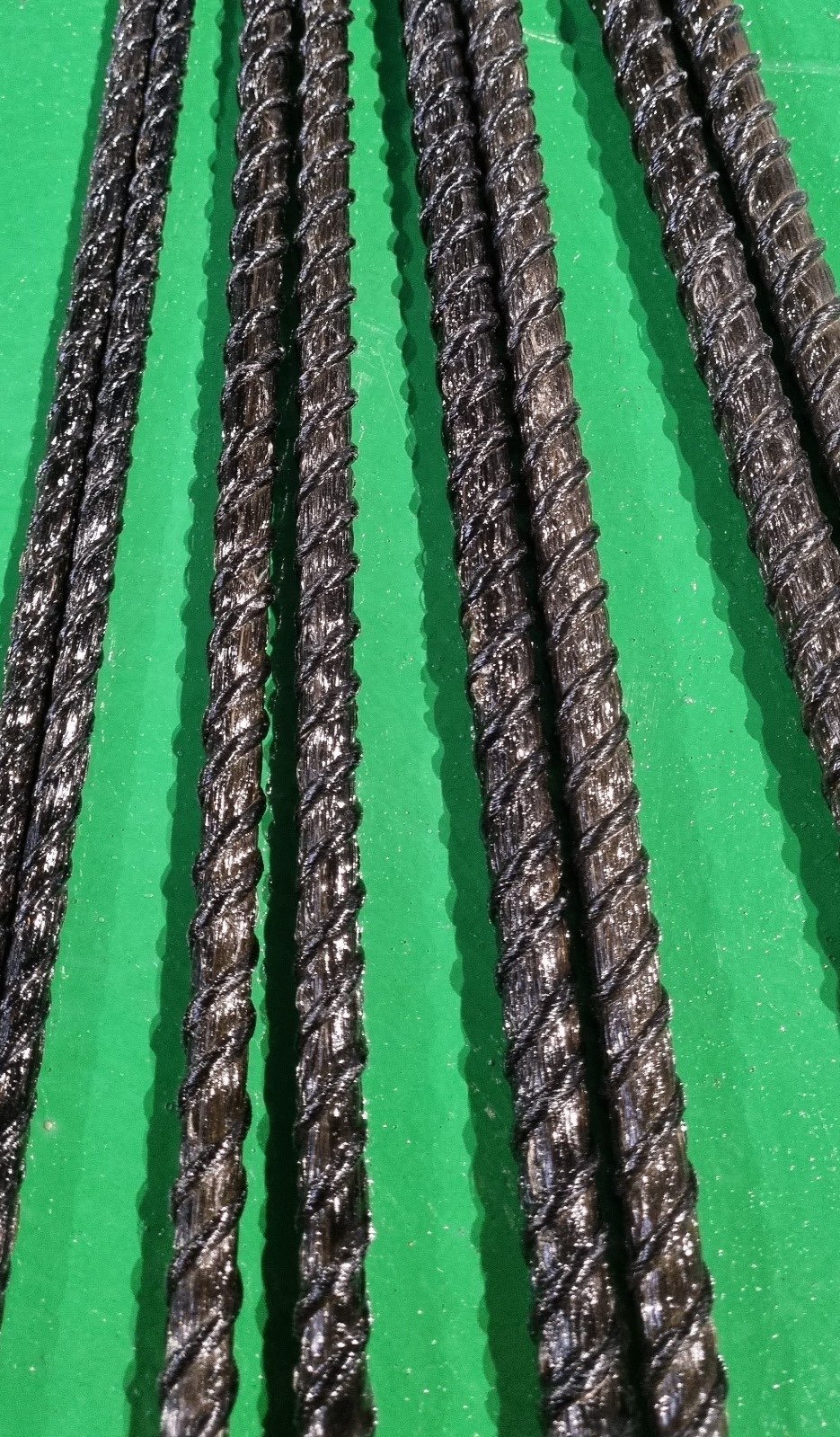

Composite Reinforcements

We manufacture composite reinforcements made from fiberglass and epoxy binders, making them resistant to corrosion. During production, a special abrasive or sand layer is applied to the surface of the reinforcement to increase adhesion with concrete by up to 100%, improving the bond between the concrete and the reinforcement.

This type of reinforcement offers an effective and more cost-efficient alternative to traditional steel reinforcement, as it replaces metal with a thinner diameter. It is primarily used in structures that require high load-bearing capacity.

Composite Mesh

We also manufacture composite mesh, which is made from fiberglass and enhances the mesh's strength. This design prevents the mesh from delaminating into individual rods, ensuring effective reinforcement.

Utilizing a special double-weaving technology, the mesh becomes more durable, remaining intact under load and not breaking or disintegrating. It is available in both rolls and sheets, is rust-resistant, five times lighter than steel, twice as strong as steel, and does not conduct heat.

Fiberglass mesh has proven highly effective for reinforcing industrial floors and walls in production and storage facilities. Thanks to its low thermal conductivity—100 times lower than steel, the heating costs for buildings are significantly reduced.

Basalt Fiber Rebar (BFR)

Cutting-edge reinforcement material made from naturally occurring volcanic rock. Unlike steel, BFR is rust-proof, lightweight, and significantly stronger, making it a superior choice for concrete infrastructure.

Corrosion Resistant – Unlike steel, BFR does not rust, extending the lifespan of concrete

structures

High Strength & Lightweight – 2.5 times stronger and 4 times lighter than steel

Eco-Friendly & Sustainable – Made from abundant basalt rock with minimal environmental impact

Cost-Effective – Reduces maintenance costs associated with steel rusting and deterioration

Thermal Stability – Minimizes cracking from temperature changes due to its low thermal expansion

Non-Conductive & Safe – Ideal for structures near power lines or sensitive equipment

Basalt Fiber Concrete Additives

Tiny rock-based fibers mixed into concrete to make it stronger, more crack-resistant, and longer-lasting.

High Strength & Durability - excellent mechanical properties, resistant to salts, acids, alkalis, and UV radiation, non-corrosive, tested 50% stronger

Heat & Fire Resistance - withstands temperatures from -269°C to 700°C (up to 1000°C for short durations), non-combustible and thermally stable

Non-Magnetic & Dielectric Properties - ideal for applications requiring minimal electromagnetic interference, suitable for sensitive instruments and electrical installations

Cost-Effective & Eco-Friendly - made from natural volcanic rock without expensive chemical additives, nearly 10 times cheaper than carbon fiber, can be fully recycled through melting, promoting circular economy principles